Elevator bolt

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Elevator Bolt?

An elevator bolt is a type of fastener commonly used in material handling applications, especially for attaching items to conveyor systems. The unique design of the elevator bolt includes a large flat or countersunk head, a shallow conical bearing surface, a square neck under the head, and a unified thread pitch.

Here’s how they’re generally used:

- Application: Elevator bolts are mainly used where a smooth surface is needed on the bolted side to prevent obstruction or interference with the operation of moving parts, such as in the floors of grain elevators and other conveyance equipment.

- Installation: The bolt is placed through a pre-drilled hole and is usually installed from the underside. The square neck is designed to fit into a square hole or to be embedded into the material to prevent it from turning when the nut is tightened.

- Tightening: A nut is screwed onto the threaded end of the bolt from the outside or the top side of the conveyor belt or system. The large flat head of the elevator bolt provides a wide bearing surface which prevents pulling through soft materials.

- Finished Surface: Because of the flat head, the finished surface remains smooth, which minimizes wear and tear on items or materials that move over or along with the fastener.

Elevator bolts are typically used in conveyor systems within industries like agriculture, construction, and manufacturing. Due to their design, they are particularly useful for fastening items to belts where the smooth head allows for the unconstrained movement of materials across the surface.

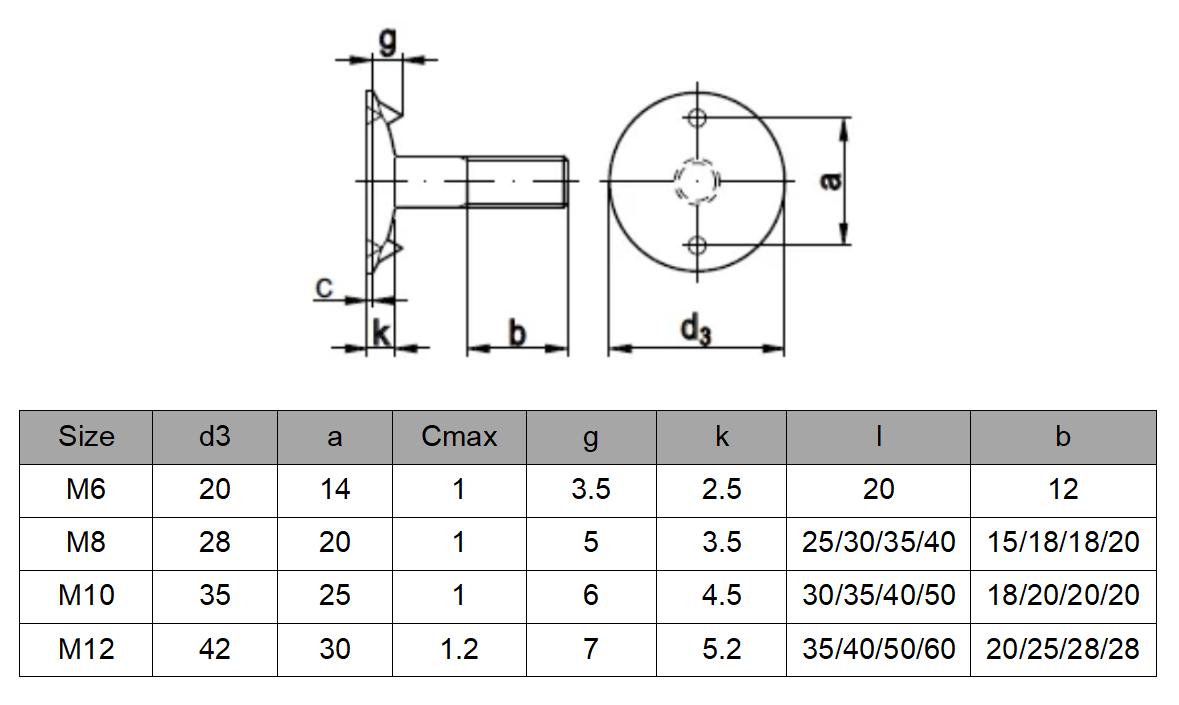

Size: M6-M12