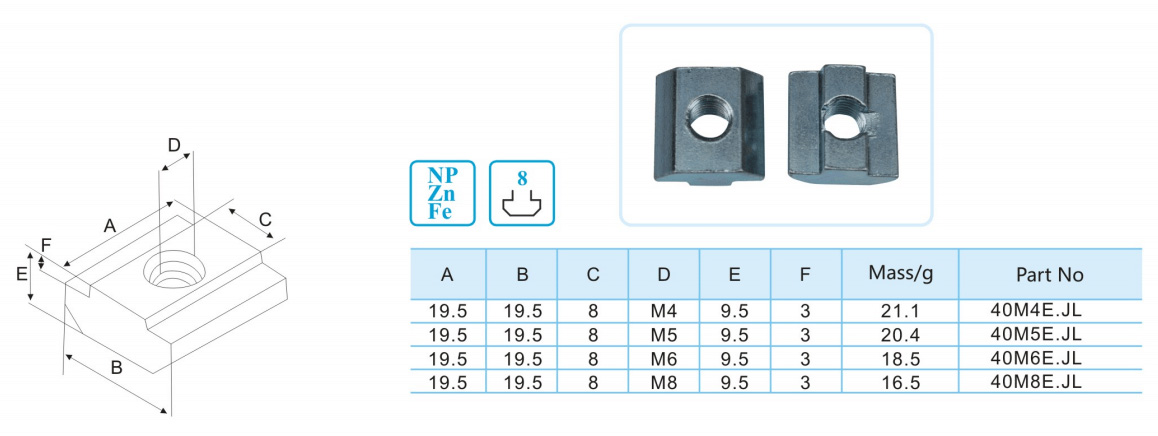

T Nuts

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is T Nut?

A T-nut, also known as a tee nut or blind nut, is a type of nut used to fasten a wood, particle, or composite material workpiece, leaving a flush surface. It has a long, thin body and a flange at one end, resembling a T in profile. The flanges can have prongs that grip the material when inserted, or it could be designed to sit flush on the surface when it’s used in through-hole applications. Here are some key aspects:

Design and Structure: The T-nut is distinguished by its T-shaped outline. It typically has a threaded hole in the center. Many T-nuts include prongs or barbs on the flange, which sink into the material when hammered or screwed in place, offering a strong, anchoring grip.

Applications: They are widely used in woodworking and metalworking for applications like furniture assembly, climbing walls, securing wheels or casters to wooden bases, and in many hobbyist projects where a strong, internal thread is needed in a wooden piece. They’re particularly valuable in applications where the backside of a panel is inaccessible, as they can be inserted from one side.

Installation: For the pronged variety, installation usually involves drilling an appropriately sized hole in the workpiece, inserting the T-nut from the back (prong side down), and securing it by hammering or pressing the prongs into the material. For through-hole applications, they can be placed in pre-drilled holes and secured with screws or bolts through the adjacent material, pulling the nut flush against the surface.

Material: T-nuts are made from various materials, including steel for strength and durability, or brass and stainless steel for corrosion resistance in outdoor or damp applications.

Size and Variants: They are available in various sizes and thread types to accommodate different bolts and applications. The choice of size and type depends on the thickness of the material being used and the load requirements of the joint or connection.

Because of their ability to provide a machine thread in wood or similar soft materials, T-nuts are an essential component in both professional and hobbyist settings, offering a reliable means of attaching components securely.