Weld Nuts

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

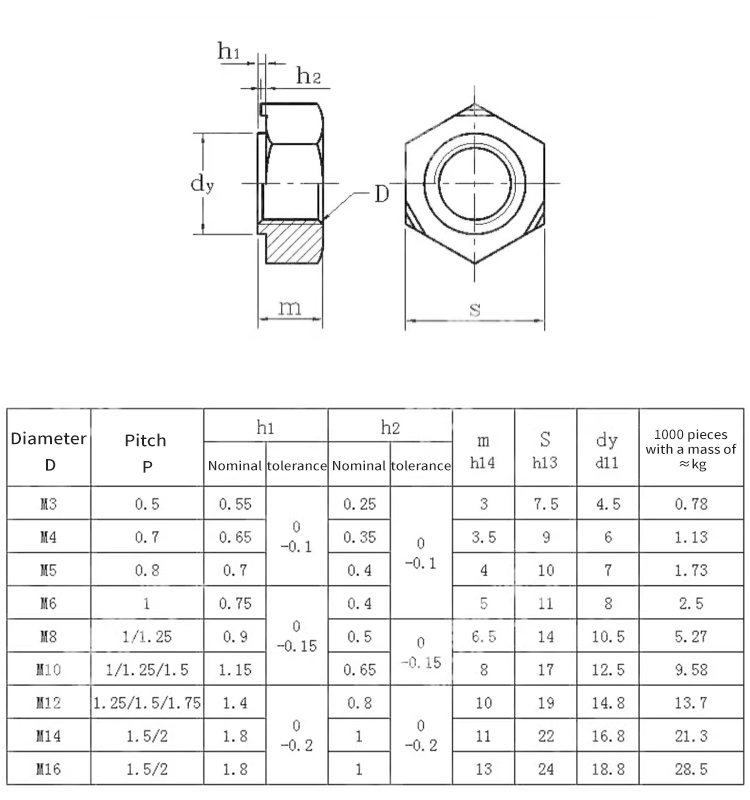

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Weld Nut?

A weld nut is a special type of nut specifically designed to be welded to another object. There are numerous types of weld nuts, each with different specifications and uses, but they generally share a few common characteristics:

- Design and Structure: Weld nuts usually have a flange with small nubs or projections that melt to form the weld. These projections concentrate the welding current, enabling a strong weld with minimal current. The nuts are designed to be welded onto a flat surface.

- Applications: Weld nuts are commonly used in the automotive industry and in metalworking applications where it’s necessary to attach a nut to a steel or metal workpiece. They also serve well in applications where the addition of a bolted connection is required after a structure is fabricated.

- Installation: To install a weld nut, the nut is placed against the workpiece in the desired location, and a welding gun is used to melt the projections on the nut onto the workpiece, securing the nut in place. This allows for bolt or screw threads to be added to a metal part where threading is not possible or practical.

- Material: They are typically made of the same material as the workpiece they are attached to, to ensure a proper weld. Common materials include stainless steel, carbon steel, and aluminum.

- Advantages: A significant advantage of weld nuts is that they offer a strong, permanent bolted connection in places that might not be easily accessible for installing a standard nut. Additionally, since they’re welded in place, they are less likely to loosen over time compared to nuts that are just mechanically fastened.

Weld nuts are a robust solution for adding a threading feature to a metal part, allowing for secure and maintenance-free bolted connections in complicated assemblies. They’re available from many fastener and welding supply sources.