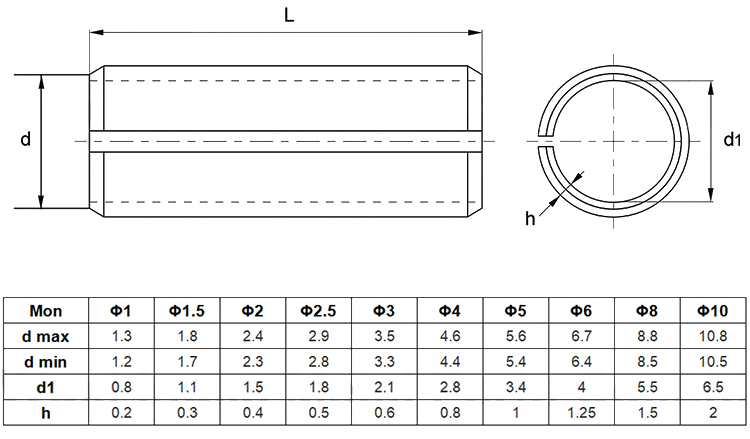

Spring Pin

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Spring Pin?

A spring pin, commonly referred to as a roll pin or tension pin, is a hollow cylindrical pin with a slot cut along its length which allows it to be compressed.

Here are some key points about spring pins:

- Function: Spring pins are used to secure the position of two or more parts of a machine relative to each other. The tension generated by the pin against the walls of the hole it is inserted into holds the pin in place.

- Material: They are typically made of carbon steel, stainless steel, or other durable materials that allow for elastic deformation.

- Design: The slot in the spring pin allows it to compress as it is driven into a hole slightly smaller than the pin’s original diameter. Once in place, the pin expands, exerting force against the walls of the hole to keep it fixed.

- Uses: They are often used in place of solid pins where a self-retaining fastener is desired. They can accommodate significant shear loads, making them useful in shear or pivot applications.

- Installation and Removal: Spring pins are relatively easy to install and remove. They require a hammer or a press for insertion and can be removed by driving them out with a punch.

- Sizes: Spring pins come in a variety of sizes to accommodate different diameters and lengths required for specific applications.

Spring pins are versatile elements used in numerous applications for temporary or permanent fastening. They are especially useful in assemblies that are subject to rotational movement or shear force.