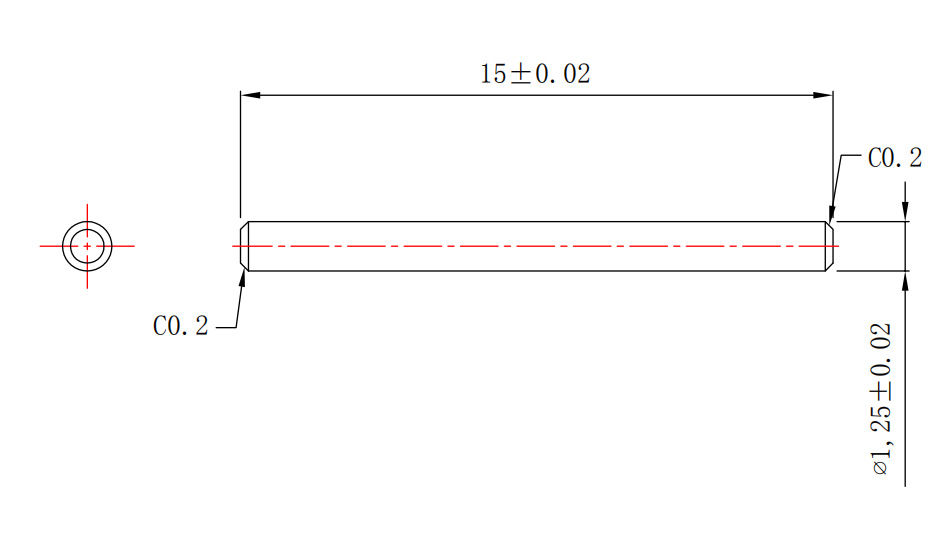

Dowel Pin

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Dowel Pin?

A dowel pin is a solid, cylindrical pin that is used to locate and secure parts together within a precision assembly or to align parts during assembly. They are commonly used in manufacturing and woodworking for a tight fit, alignment, and joint stability.

Here are the important aspects of dowel pins:

- Material: Dowel pins can be made from various materials, including hardened steel, stainless steel, alloy steel, or wood. The choice depends on the strength requirements and the environment in which they will be used.

- Types: There are several types of dowel pins, including pull dowels, which have a threaded hole at one end for removal; precision dowel pins, which are ground to tight tolerances; and grooved dowel pins, with longitudinal grooves to allow for more glue or adhesive surface when used in wood.

- Uses: They are inserted into receiving holes, often with an interference fit, to align and hold different parts of a machine or furniture together. They can carry significant loads and resist rotational motion.

- Installation: Installation may require a press fit, also known as an interference fit, where the dowel is slightly larger than the hole. Alternatively, a slip fit, where the dowel easily slides into the hole, can be used when ease of assembly and disassembly is needed.

- Precision: Dowel pins often have a tight tolerance to ensure a precise fit. They are precision-machined for accurate alignment and are important in applications where high levels of accuracy are required.

- Standard Sizes: They are typically manufactured to standard sizes ranging from very small diameters for electronics or medical devices, to large diameters for heavy machinery.

Dowel pins are a key component in providing precision and strength in a variety of assemblies, serving both as a fastener and an alignment device. They are generally not meant to be removed frequently once installed.