Cotter Pin

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

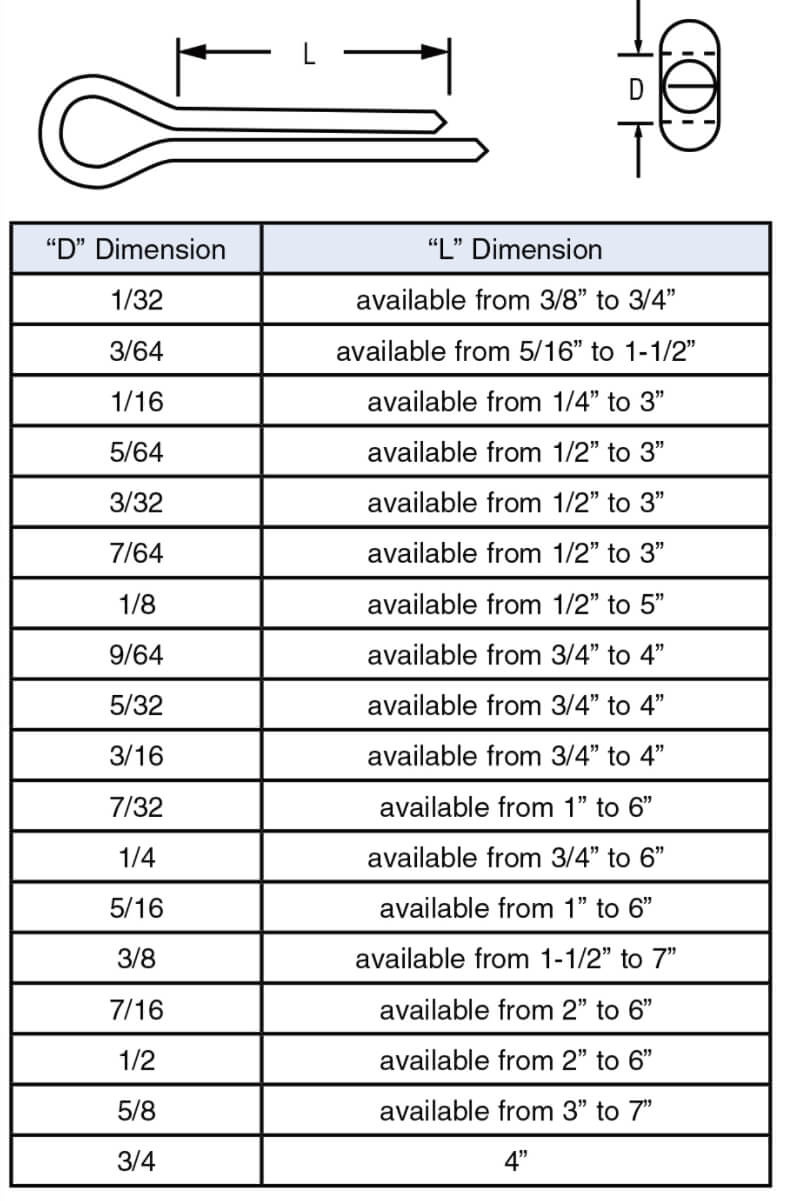

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Cotter Pin?

A cotter pin, also known as a split pin, is a fastener that is commonly used to secure two items together, typically to prevent a nut from turning or a bolt from sliding out. It consists of a metal pin with two tines that are bent during installation to hold it in place.

Here are some key points about cotter pins:

- Design and Usage: A cotter pin has a long body with a loop at one end, which makes the insertion easier. After inserting the pin through holes in the bolt and the part it passes through, the ends (or tines) of the pin are separated and bent to lock the pin in place. This prevents axial movement.

- Applications: Cotter pins are used in various applications such as securing the wheel nuts on axle assemblies, in car suspensions, and in other machinery where a part needs to be affixed solidly but still be easy to remove.

- Material: They are usually made from soft metals such as aluminum or steel, which makes them easy to bend. In some cases, stainless steel or brass pins are used for added corrosion resistance.

- Installation: Properly installing a cotter pin involves sliding the pin into the hole and bending the ends of the pins in opposite directions. It’s important that the bend is clean and that the pin is not weakened by excessive bending back and forth.

- Removal: To remove a cotter pin, the bent ends are straightened so that the pin can be slid out easily. Since this process can sometimes damage the pin or make it less secure upon re-use, cotter pins are considered semi-permanent and are often replaced with new ones rather than being reused.

Cotter pins are a reliable and straightforward method for securing components in mechanical applications where easy disassembly is desired but safety cannot be compromised. They come in various sizes to suit different diameters of holes and thicknesses of fastened assemblies.