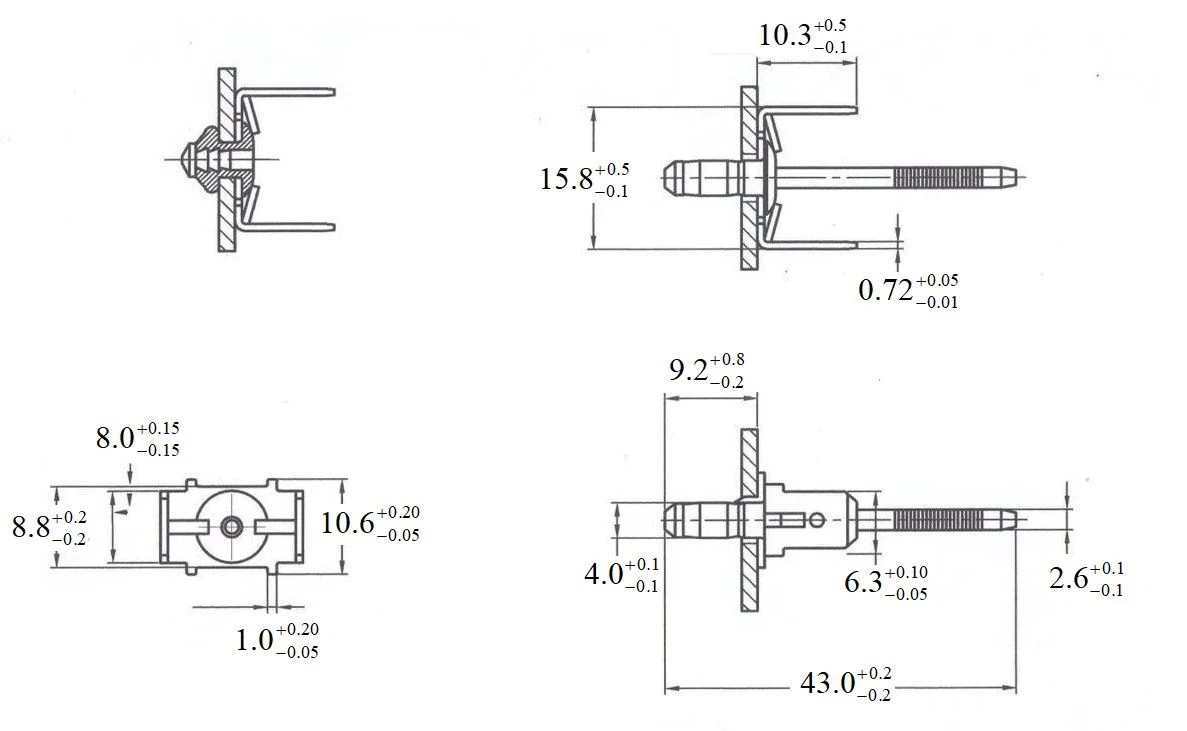

Grounding Rivet

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

A grooved type blind rivet is a specialized fastener designed for joining materials or components where access is only available from one side. It’s used in a variety of applications where standard rivets can’t be used. Here’s a summary:

Structure: These rivets have a grooved shank that expands as the mandrel is pulled through during installation, increasing holding power.

Material: They are typically made from metals like aluminum, steel, or stainless steel for durability.

Installation: Using a rivet gun, the rivet is placed into a pre-drilled hole and the tool pulls the mandrel through the body. The grooves in the shank grip the material, creating a secure joint.

Design Advantage: The grooved design ensures stronger attachment in soft or brittle materials by “gripping” into the material to prevent pull-out.

Applications: Commonly found in automotive, construction, and home improvement projects, especially when working with plastic, fiberglass, wood, or laminates.

Grooved type blind rivets provide a reliable solution when there’s limited access to the joint and a strong hold is necessary. They are user-friendly and can be quickly installed, making them popular in a multitude of settings.