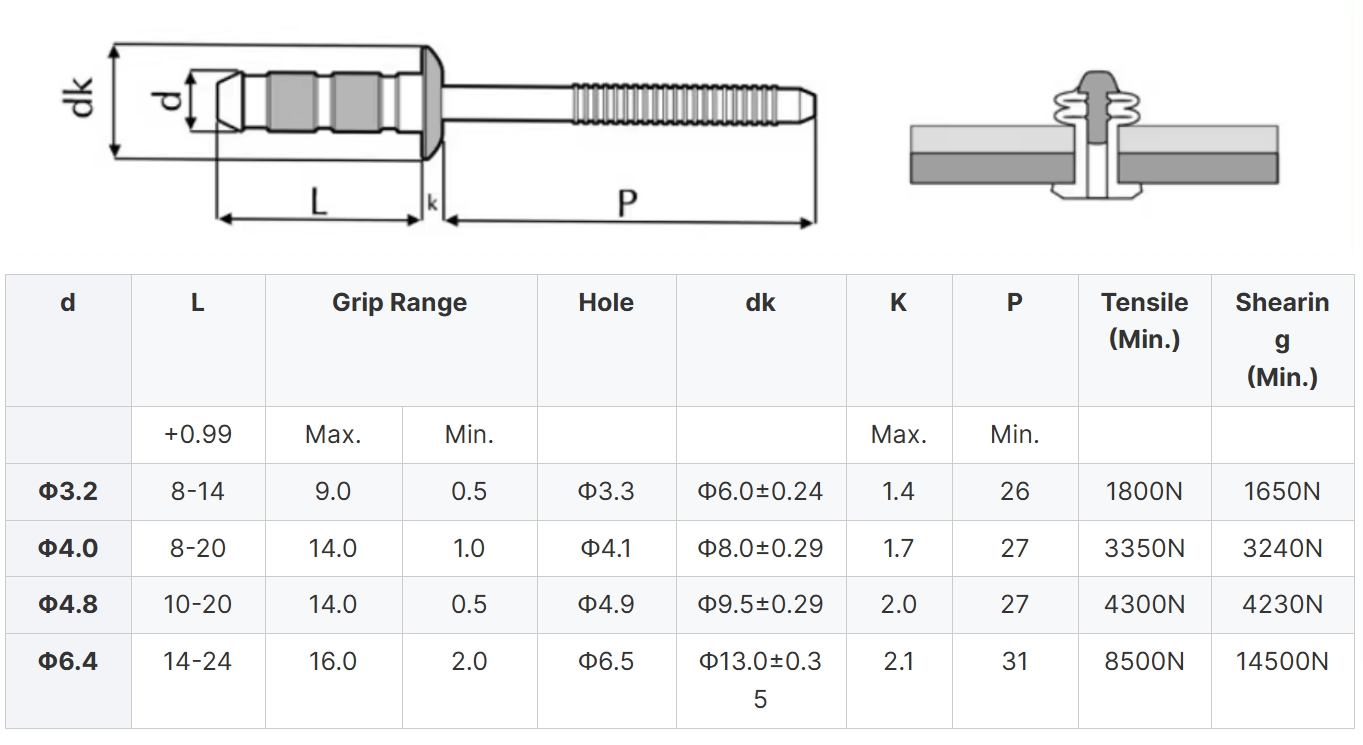

Muti-Grip Blind Rivets

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

A Mono-Lock blind rivet, also known as a “monobolt”, is a type of blind rivet that is designed for high strength and vibration resistance. Here’s how it stands out:

Construction: These rivets are designed as a one-piece assembly, which means the mandrel is retained within the rivet body once installed. This design offers a permanent and vibration-proof hold.

Installation: They are installed from one side of the workpiece, making them ideal for applications where the other side is not accessible. The unique design ensures a fully locked mandrel after installation.

Materials: Mono-Lock rivets can be made from a variety of materials, including aluminum, steel, and stainless steel to accommodate different environmental conditions and material types.

Applications: Due to their robust nature, they are often used in applications that require a high-strength connection, such as in the transportation industry for truck bodies, trailers, and railcar manufacturing.

Advantages: Their superior hold and vibration resistance make them very reliable in applications where security and safety are critical. The retained mandrel provides added assurance against failure.

Mono-Lock blind rivets are trusted in demanding applications where traditional blind rivets might not stand up to the stress, offering a combination of accessibility, strength, and durability.