Rivet Nuts

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Rivet Nut?

A rivet nut, also known as a blind rivet nut or a rivnut, is a uniquely designed mechanical fastener that can create a strong, threaded hole in thin materials or in applications where only one side of the workpiece is accessible. It is essentially a one-piece internally threaded and counterbored tubular rivet that can be anchored from a single side.

Here are some noteworthy points about rivet nuts:

- Strength: When installed, hex body rivet nuts can be almost ten times stronger than typical, knurled round body rivet nuts, providing high shear and tension strength. This makes them an upgrade over traditional bolt and nut applications, particularly in cases where the joint may be subjected to stress or vibration.

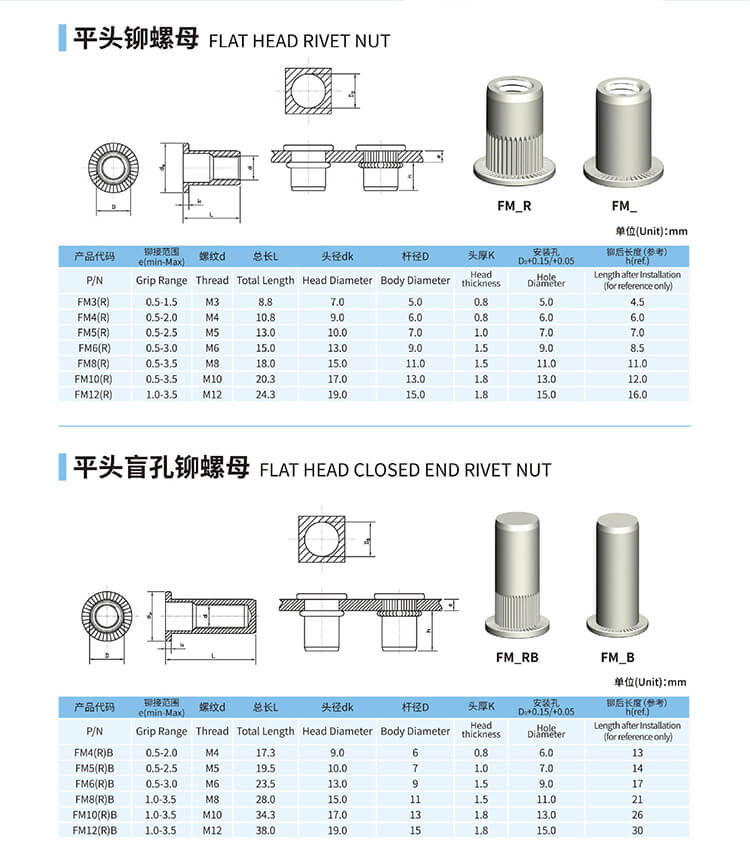

- Sizes: Rivet nuts come in a wide range of sizes, from small to large diameters (e.g., 1/4-20 to 1/2-13 and M6 to M12), and they’re available in both small flange and large flange styles.

- Types: There is a diversity of rivet nuts, including round rivet nuts, hexagonal rivet nuts, slotted rivet nuts, swaged rivet nuts, floating rivet nuts, and rivet nut studs. This variety allows for use in different materials and applications, providing versatility in fastening solutions.

- Application: Rivet nuts are particularly useful in creating a strong thread in thin materials or in tube-like structures where you wouldn’t be able to secure a nut behind the material. They’re also useful for applications that necessitate occasional removal or disassembly.

Rivet nuts are widely used in automotive, aeronautics, electronics and construction industries due to their ease of installation and the robust, threaded interface they provide in thin sheet materials. They’re installed using a special tool that pulls the body of the rivet nut up, causing the backside to flare out and clinch the material, which provides a secure, threaded hole ready for a bolt or screw.