Sealed Type Blind Rivets

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

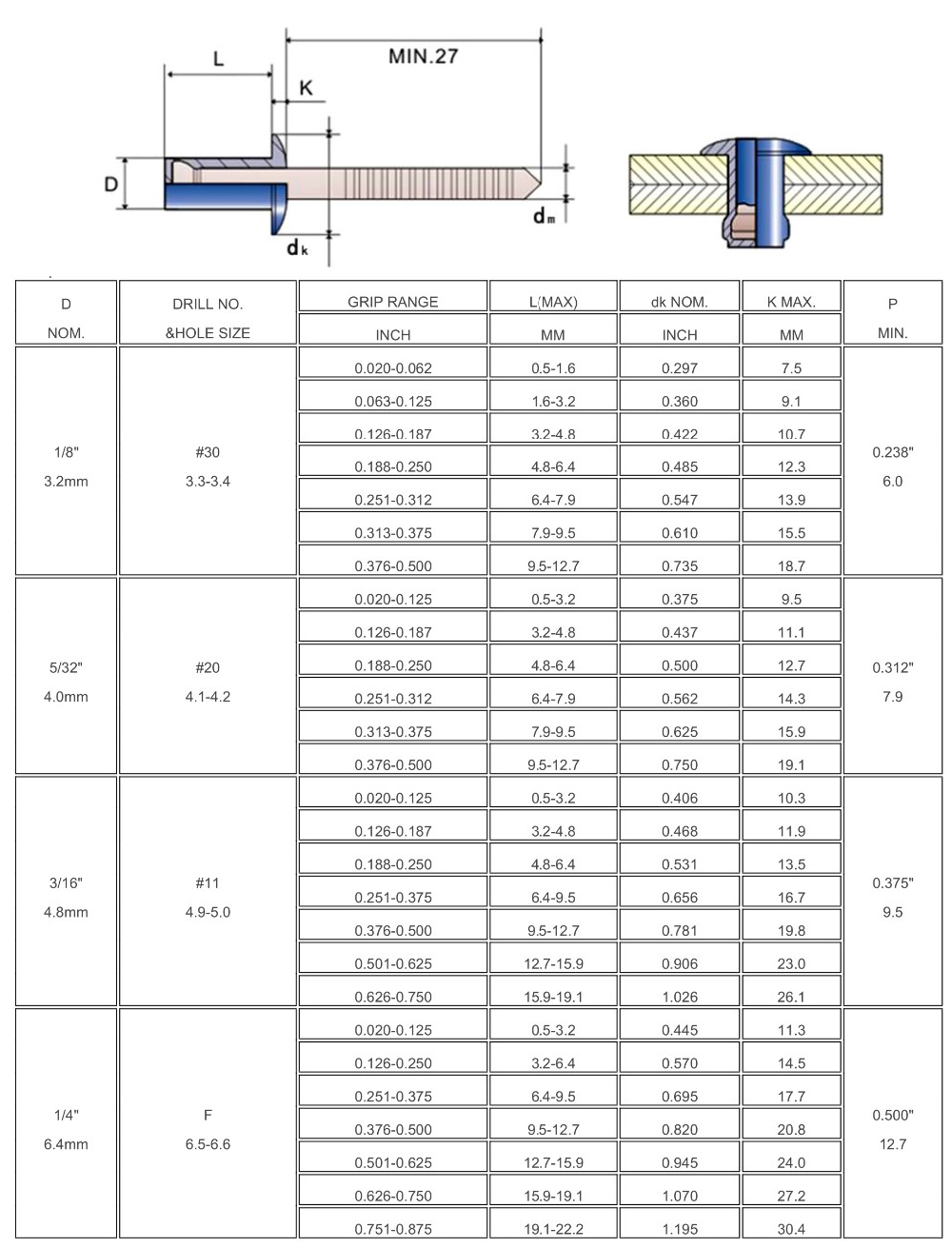

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

Sealed type blind rivets, also known as closed-end blind rivets, have a closed end that forms a watertight seal upon installation. Notable features include:

Sealing Capability: The closed end of these rivets provides a seal that prevents the passage of liquids or gases, making them suitable for applications where this is a critical requirement.

Design: Upon setting, the sealed end also prevents the entry of dirt and other contaminants, which can be beneficial for maintaining the integrity of the internal components.

Material Choices: These rivets can be crafted from different materials, such as aluminum, stainless steel, or steel, to cater to varied mechanical and environmental demands.

Use Cases: Sealed type blind rivets are typically used in applications such as tanks, containers, or any other assemblies where airtight or watertight seals are necessary.

Installation: They are installed from one side of the workpiece, which is advantageous in spots that are tricky to access.

Advantages: Aside from their sealing properties, these rivets can also provide strong and reliable joints, with added benefits in terms of corrosion resistance and durability.

Sealed type blind rivets are particularly essential in applications that require robust, leak-proof fastening solutions, offering protection against moisture and other environmental factors.