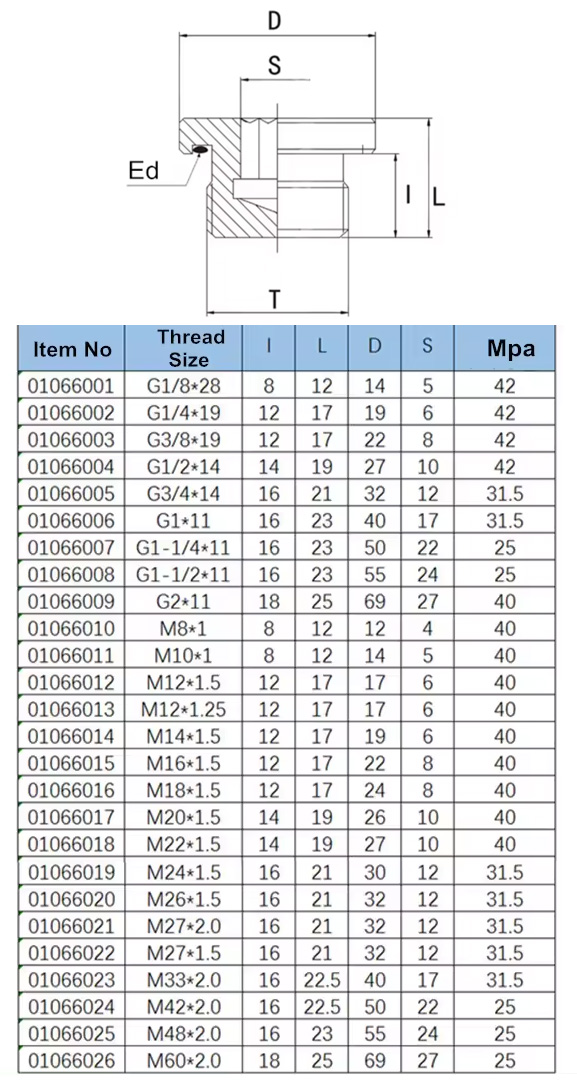

Sealing Oil Plugs

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

What is Sealing Oil Plugs?

Sealing oil plugs, often referred to as oil drain plugs, are crucial components in the maintenance and operation of engines and machinery.

Here’s a basic overview:

- Purpose: Their primary function is to seal or close off the oil drain port of an engine, gearbox, or hydraulic system. This prevents oil from leaking out and also allows for the controlled drainage of oil during maintenance or oil changes.

- Design: These plugs are typically made from metals such as steel or aluminum to withstand the harsh environment within an engine or gearbox. They come with a hexagonal head or socket head for easy opening and closing with a wrench or socket.

- Sealing Mechanism: To ensure a leak-proof seal, sealing oil plugs often have a washer or gasket, which can be made of metal, rubber, or a combination thereof. When the plug is tightened, this washer compresses, creating a seal that prevents oil from escaping.

- Applications: Beyond their use in vehicles, sealing oil plugs find applications in various types of machinery and equipment that require oil for lubrication, cooling, or hydraulic purposes.

- Maintenance: It’s essential for the plug and its sealing washer to be checked regularly and replaced as needed to avoid oil leaks. This is especially important after each oil change to ensure the integrity of the seal.

These components play a key role in the overall health and efficiency of engines and other mechanical systems, making regular inspection and maintenance vital.