Wave Washers

Standard: DIN, ASTM, JIS

Material: Stainless steel, Duplex Steel, Carbon Steel, Brass, Aluminum, etc

Plating: Zinc, Black Oxide, Dacromet, Geomet, Passivate, etc

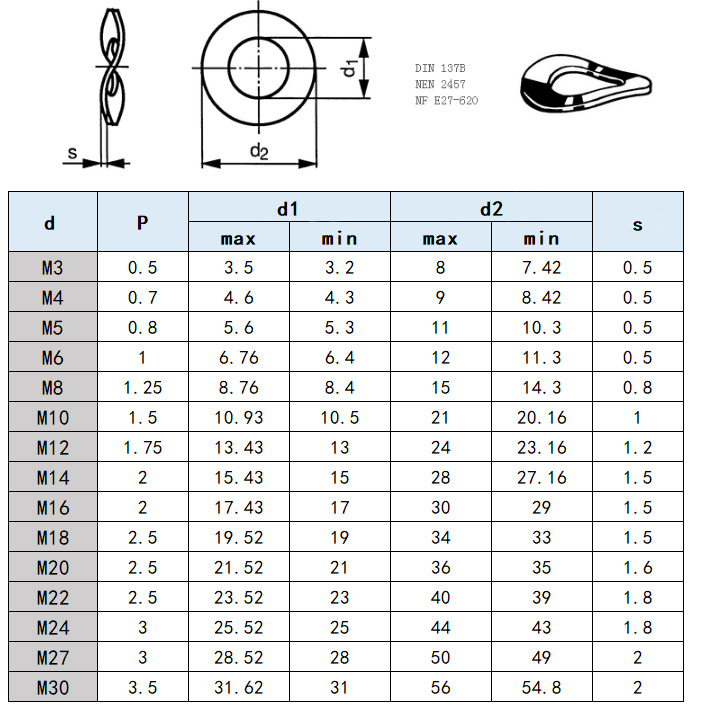

Size: 1/4”-1”, M3-M48, Customized

MOQ: Accordingly to the size

Description

Wave washers, also known as wave disc springs, are a type of washer that are used for shock absorption, load bearing, and to provide a preload or flexible quality to a bolted joint or bearing.

The distinctive feature of wave washers is their wave-like design, which are actually a number of curvilinear waves, often three or four, around the circumference of the washer. When a load is applied, the waves flatten out, creating pressure and maintaining the assembly’s positioning.

Since wave washers can produce relatively large loads with small deflections, they are great for applications with limited space. Additionally, their unique design allows them to absorb shock and moderate loads, making them perfect for cushioning and vibration control applications.

Wave washers are typically made of spring steel, stainless steel, or copper, but can also be made from other materials. They are available in a range of sizes and dimensions to fit different bolt or shaft sizes and different load requirements.